Insert Advertising remains a unique platform for showcasing products and services. Print is tangible, has impact, it gets response and is remembered. Inserts stand out from the product they are placed in and allow for a variety of options such as size, shape, paper, pagination, finishing options, paginations (up to 96pp in our titles), scented ink or samples – we have inserted health & beauty products, CDs to household cleaning products and food samples. Designers and marketers have many opportunities to be creative. They offer the dual benefit of branding and direct response at a relatively low cost.

Inserts have high visibility and impact and can often outlive the media they are delivered with because they can be removed and kept or passed on to friends and family. With a choice of a national or a regional campaign targeting of specific locations for new store openings, bespoke messaging, coupons or codes is available every day of the week.

One of the biggest misconceptions about print and insert advertising is the lead time. For example, upon receipt of print ready artwork, we can print, insert and be in the hands of the consumer within 48-72 hours – with six UK based print sites this can reduce not only lead time and delivery costs but also the risk associated with deliveries as the insert can be printed and inserted from from one location.

Trust is high on the agenda right now, and when readers choose to buy a newspaper, the advertiser has a dedicated audience – newsbrands command a high level of attention, attention drives a powerful response. It is true that newspapers may not be performing as strongly as they historically have, but what they do still offer is reach and consumer trust, last year, we sold 540 million newspapers and across five of our print sites we inserted 375 million commercial inserts and 80 million magazines – marketers cannot downplay this medium as part of the marketing mix, and as data protection rules tighten if offers the opportunity to reach a new audience without handling data.

Commercial insert bookings are entered into our booking system, called Neon, which covers all Reach print sites as well as third party printers. This enables the Reach Solutions team to take bookings for national and/or regional campaigns across multiple titles offering huge reach available everyday of the week.

Inserts can be printed at our sites in a range of formats, paperstocks and finishes. The advantage of printing and inserting from the same location not only reduces lead time (we can print, insert and be in the hands of millions of consumers within hours) but it can also reduce the costs and potential risk associated with delivery or even a rejected insert arriving on site.

That being said, we receive deliveries from third party printers regularly, and just need to be made aware of the format, paperstock, pagination and full details to ensure that our machines are capable of inserting.

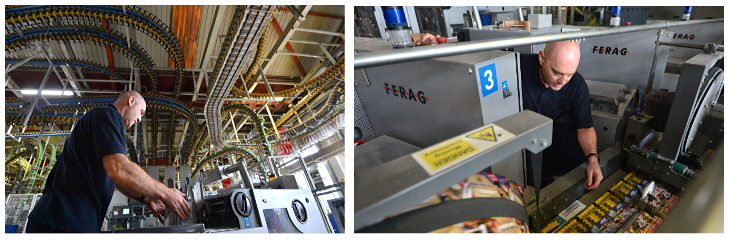

Once the booking appears, the print schedule is arranged and the decision is made – from the pagination and dimensions – whether a product should be disc fed, as shown below.

Or if they will be hopper fed – where the inserts are manually placed into the machines.

The decision to disc or hopper feed determines when the print site requires the insert and when staff, are required to be on site. Disc fed products need to be on site five days before production if coming from an external printer. If printed on site, this can be reduced. Hopper fed products are required two days before production as these products are inserted into the live production run.

Each insert advertising campaign has a unique reference number. If the insert is being delivered by an external printer (not printed at our site), they will need to contact us to arrange a delivery day and time by quoting the URN. Each print site determines this and we can’t accept deliveries, for security and planning reasons, unless it has been booked and arrives at the allocated time. We receive hundreds of deliveries and so the presentation of the delivery must conform to our standards and whilst drivers must adhere to our health and safety standards.

On the day of production the discs or pallets are placed on the appropriate machinery and await the presses to start. When the presses start production the product that will carry the insert (or main jacket) is transported by grippers to the inserting area:

The main jacket will need an overlap, as shown below, which is about 10mm difference in alignment and enables our machines to open the book and insert the product.

The main jackets enter the drum where it is opened in the centre, by an opening device on the drum pushing the bottom section of the overlap, shown below. It is then transported through the drum, and the commercial, magazine, sample or supplement is inserted. We have the capability to insert up to two magazines and three commercials into each main jacket.

Once inserted the copy leaves the drum it is transported to Publishing (or despatch area). Stackers turn the copies into bundles. The amount of copies in a bundle (or bundle size) is determined depending on weight and height to comply with health and safety standards which state that each bundle cannot exceed 15 kg.

Once the bundle is created in the stacker it is then ejected onto our PKT system, which acknowledges the bundle and assigns to the correct palletiser for that product.

Once the bundle reaches the correct palletiser it is pushed onto the pallet along with the rest of the copies for that product. Pallets are made up of ten bundles per layer and six layers high. The pallet is then removed from the palletiser area, shrink wrapped and sent out ready for transport.

Once on the vanway, fork lift trucks (FLT’s) remove the pallet from the transfer area and place it on the assigned vehicle to transport the copies to the designated wholesaler or delivery point.